Tlhahlobo ea Ts'ebetso ea Mohala oa Tlhahiso

Die retrorei im technischen prozess

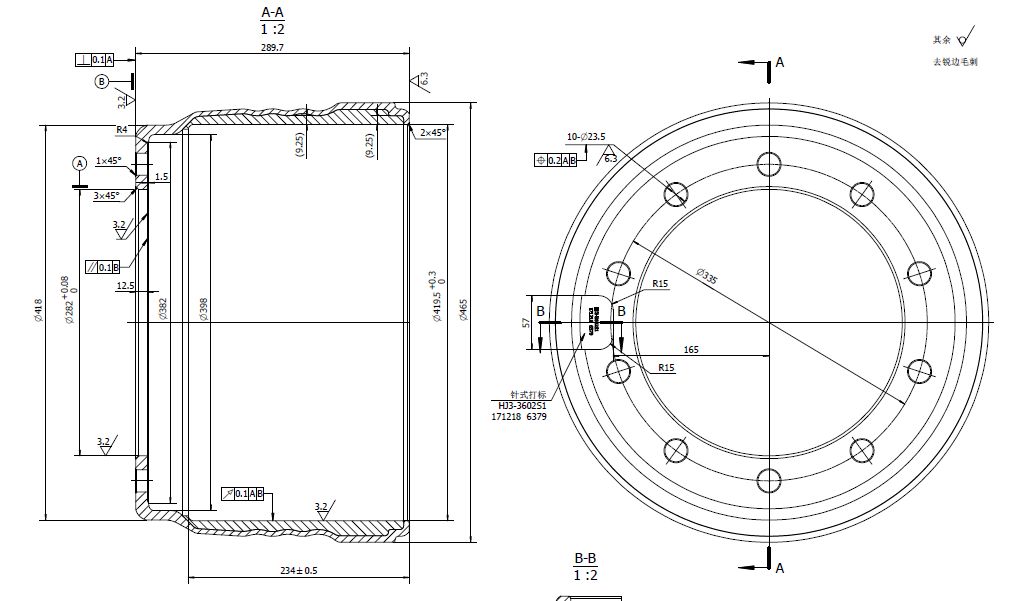

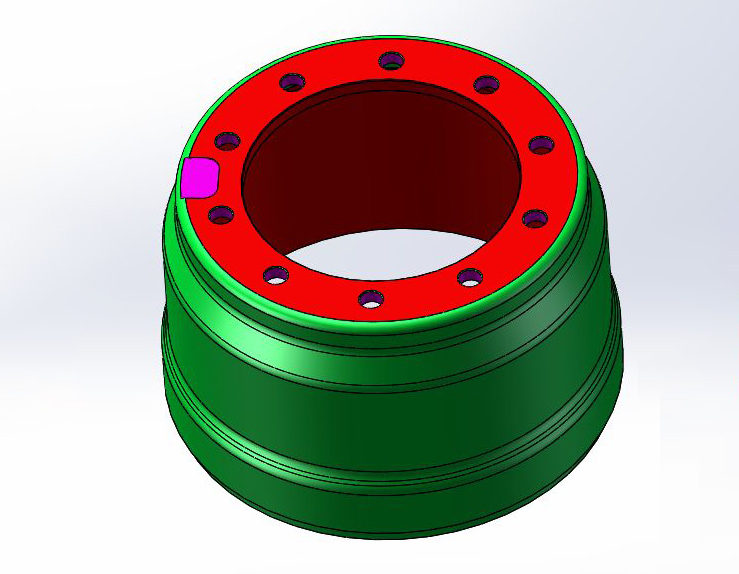

1. Mokhoa o lahliloeng oa clamping o amoheloa nakong ea ho phethoha. Ho fetola likarolo tsohle tsa machining, ho kenyelletsa le bokaholimo ba li-workpieces.

2. Nakong ea ho cheka, li-clamps tsa hydraulic li tla sebelisoa ho fumana ka bophara ba ka hare ba Φ282 le sefahleho se ka holimo, ho phunya lesoba le 10-Φ23.5 le ho phunya ka mahlakoreng ka bobeli, le ho sila sebaka sa ho tšoaea pneumatic;

Lethathamo la Lisebelisoa

| OP10 machining Cycle timer | |||||||||||||||

| Tlhaloso ea Tsela |

| ||||||||||||||

| Moreki | Lisebelisoa tsa mosebetsi | 45 | Mohlala oa sesebelisoa sa mochini | Tlaleho ea Nomoro. | |||||||||||

| Lebitso la Sehlahiswa | Seha sesebelisoa shaft welded likarolo | Setšoantšo sa No. | Letsatsi la ho itokisetsa | 2021.1.19 | E entsoe ke | ||||||||||

| Mohato oa ts'ebetso | Thipa No. | dikahare tsa machining | Lebitso la Sesebelisoa | Ho Seha Diameter | Ho poma lebelo | Lebelo la ho potoloha | Fepa ka phetohelo | fepa ka sesebelisoa sa mochini | Palo ea li-cuttings | Mokhoa o mong le o mong | Nako ea ho sebetsa | Nako e sa sebetseng | Tiisa le ho lokolla | Nako ea ho fetola lisebelisoa | |

| Che. | Che. | Desorptions | Lisebelisoa | D mm | VcM/mets | R pm | mm/Tšen | mm/Mots | Linako | Bolelele mm | Karolo | Karolo | Karolo | ||

| 1 | T01 | Senya sefahleho se ka holimo ka thata | 455.00 | 450 | 315 | 0.35 | 110 | 1 | 20.0 | 10.89 | 3 | 3 | |||

| 2 | T02 | Lathe hoo e ka bang DIA 419.5 bore, DIA 382 step face le DIA 282 ka hare bore | 419.00 | 450 | 342 | 0.35 | 120 | 1 | 300.0 | 150.36 | 3 | 3 | |||

| 3 | T03 | Lathe qetellong sefahleho hantle | 455.00 | 450 | 315 | 0.25 | 79 | 1 | 20.0 | 15.24 | 3 | ||||

| 4 | T04 | Lathe hantle DIA 419.5 ka hare bore, DIA 382 step face le DIA 282 hare bore | 369.00 | 450 | 388 | 0.25 | 97 | 1 | 300. 0 | 185.39 | |||||

| 5 | T05 | Lathe reversely le hoo e ka bang ka tlaase qetellong sefahleho | 390.00 | 420 | 343 | 0.35 | 120 | 1 | 65.0 | 32.49 | 3 | ||||

| 6 | T06 | Lathe reversely le hantle ka tlaase qetellong sefahleho | 390.00 | 450 | 367 | 0.25 | 92 | 1 | 65.0 | 42.45 | 3 | ||||

| Tlhaloso: | Nako ea ho khaola: | 437 | Ea bobeli | Nako ea ho koala ka thepa le ho kenya le ho koala thepa: | 15.00 | Ea bobeli | |||||||||

| Nako e thusang: | 21 | Ea bobeli | Kakaretso ea lihora tsa mosebetsi oa mochini: | 472.81 | Ea bobeli | ||||||||||

| OP20 machining Cycle timer | |||||||||||||||

| Tlhaloso ea Tsela |  | ||||||||||||||

| Moreki | Lisebelisoa tsa mosebetsi | HT250 | Mohlala oa sesebelisoa sa mochini | Tlaleho ea Nomoro. | |||||||||||

| Lebitso la Sehlahiswa | Moropa oa brake | Setšoantšo sa No. | Letsatsi la ho itokisetsa | 2021.1.19 | E entsoe ke | ||||||||||

| Mohato oa ts'ebetso | Thipa No. | dikahare tsa machining | Lebitso la Sesebelisoa | Ho Seha Diameter | Ho poma lebelo | Lebelo la ho potoloha | Fepa ka phetohelo | fepa ka sesebelisoa sa mochini | Palo ea li-cuttings | Mokhoa o mong le o mong | Nako ea ho sebetsa | Nako e sa sebetseng | Tiisa le ho lokolla | Nako ea ho fetola lisebelisoa | |

| Che. | Che. | Desorptions | Lisebelisoa | D mm | VcM/mets | R pm | mm/Tšen | mm/Mots | Linako | Bolelele mm | Karolo | Karolo | Karolo | ||

| 1 | T01 | Cheka lesoba le ntseng le hola la 10-DIA 23.5 | Boro e tlase-ea-ho-hole DIA 23.5 | 23.50 | 150 | 2033 | 0.15 | 305 | 10 | 15.0 | 29.52 | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 motsoako oa reaming chamfering cutter | 30.00 | 150 | 1592 | 0.20 | 318 | 10 | 3.0 | 6.65 | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Back orifice chamfering | DIA 22 reverse chamfering cutter | 22.00 | 150 | 2171 | 0.20 | 434 | 10 | 3.0 | 4.14 | 40 | 5 | ||

| 4 | T08 | Sebaka sa ho Tšoaea sa Milling | DIA 30 lisekoere tšilo ea mahetla | 30.00 | 80 | 849 | 0.15 | 127 | 1 | 90.0 | 42.39 | 4 | 5 | ||

| Tlhaloso: | Nako ea ho khaola: | 82 | Ea bobeli | Nako ea ho koala ka thepa le ho kenya le ho koala thepa: | 30 | Ea bobeli | |||||||||

| Nako e thusang: | 104 | Ea bobeli | Kakaretso ea lihora tsa mosebetsi oa mochini: | 233.00 | Ea bobeli | ||||||||||

Kenyelletso ea Mohala oa Tlhahiso

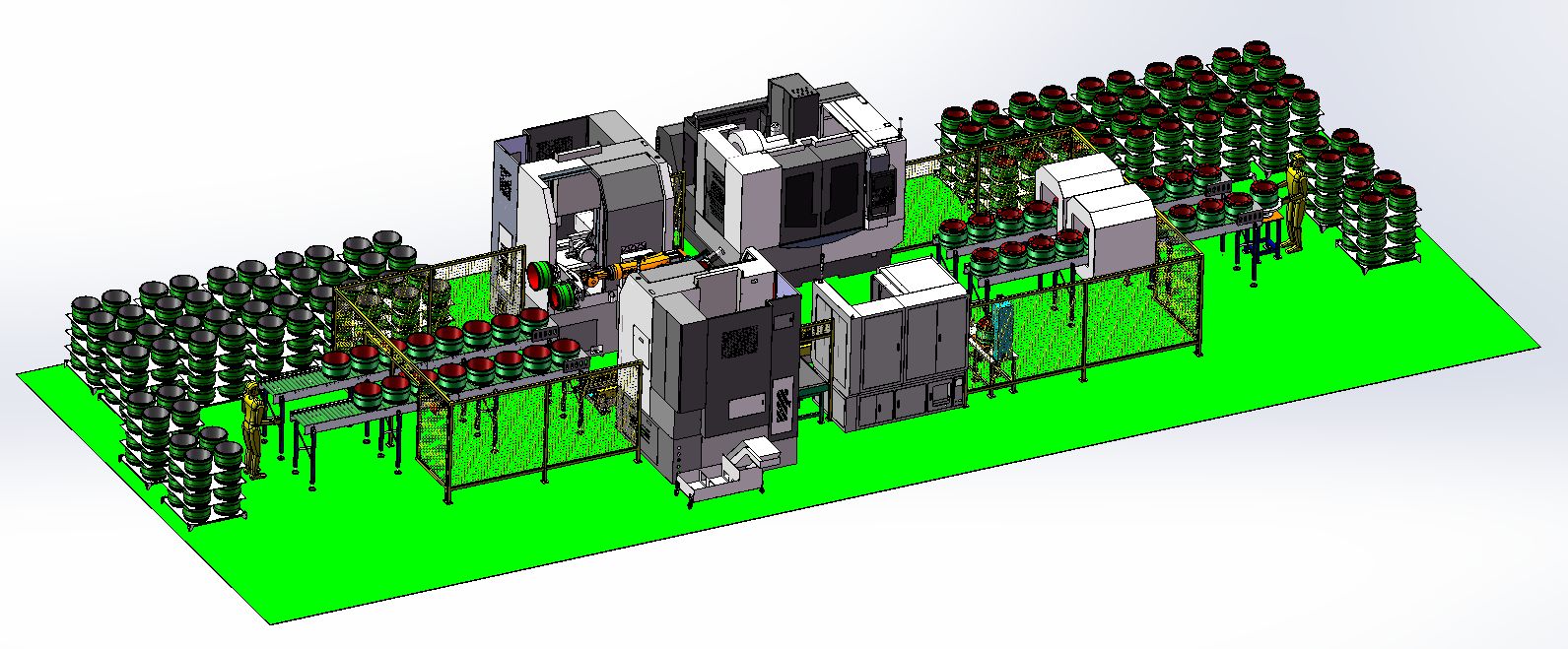

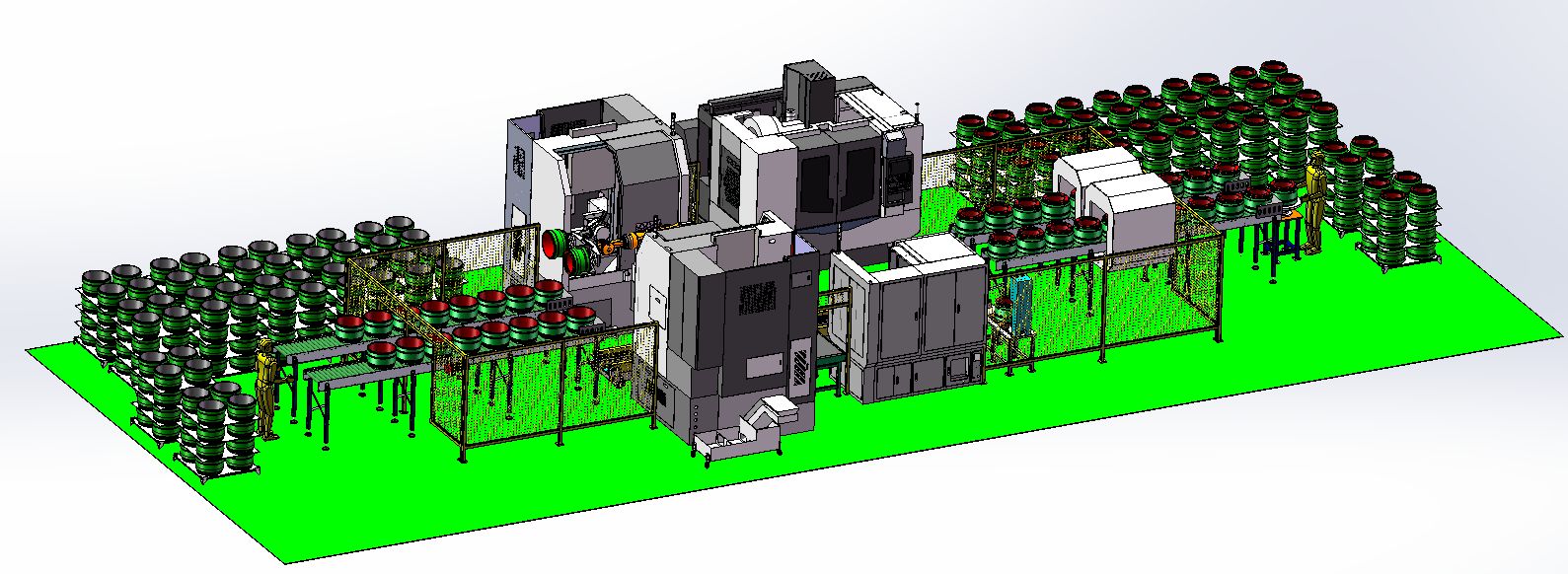

Sebopeho sa Mohala oa Tlhahiso

Kenyelletso ea Mohala oa Tlhahiso

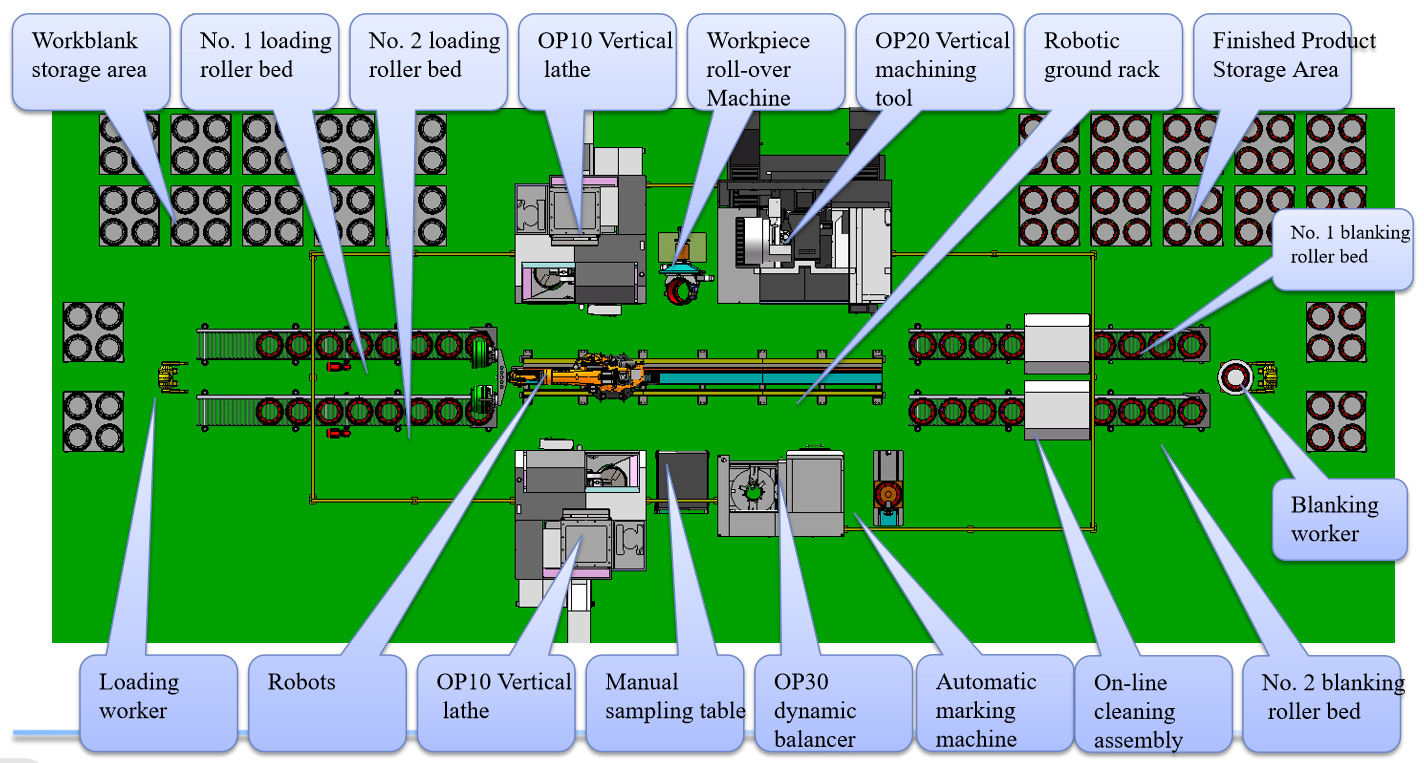

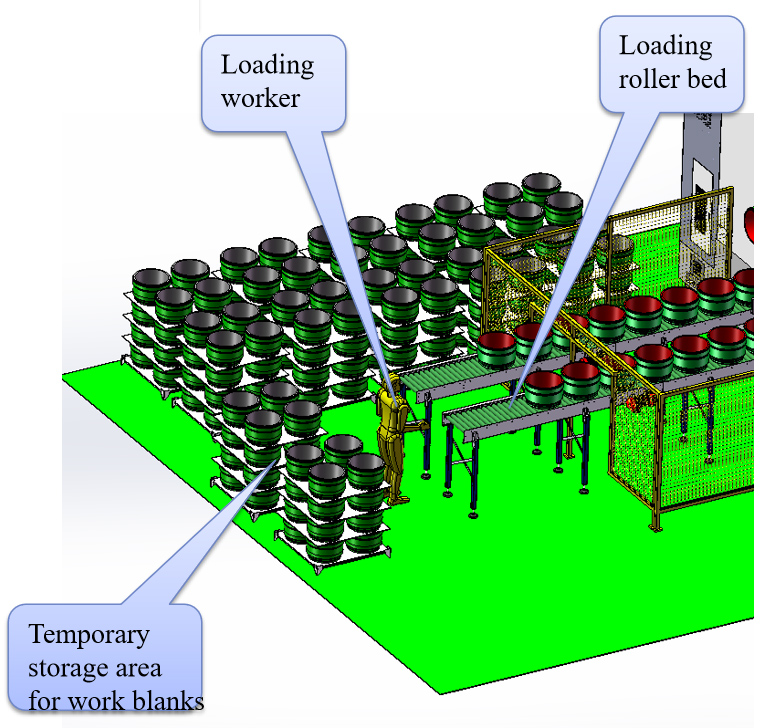

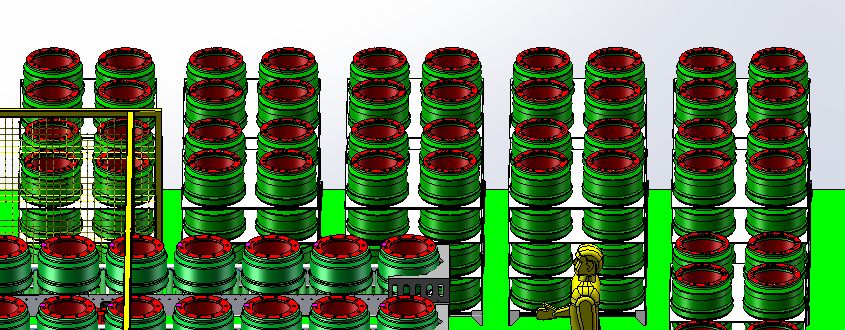

Mohala oa tlhahiso o na le yuniti e le 'ngoe ea ho kenya, yuniti e le 1 ea mochini oa lathe le yuniti e le 'ngoe e sa sebetseng. Liroboto li tsamaisa thepa lipakeng tsa liteishene ka har'a yuniti ka 'ngoe. Li-forklift li beha libaskete ka pel'a likarolo tsa ho kenya le ho koala; Mohala oa tlhahiso o akaretsa sebaka sa: 22.5m×9m

Tlhaloso ea mohala oa tlhahiso

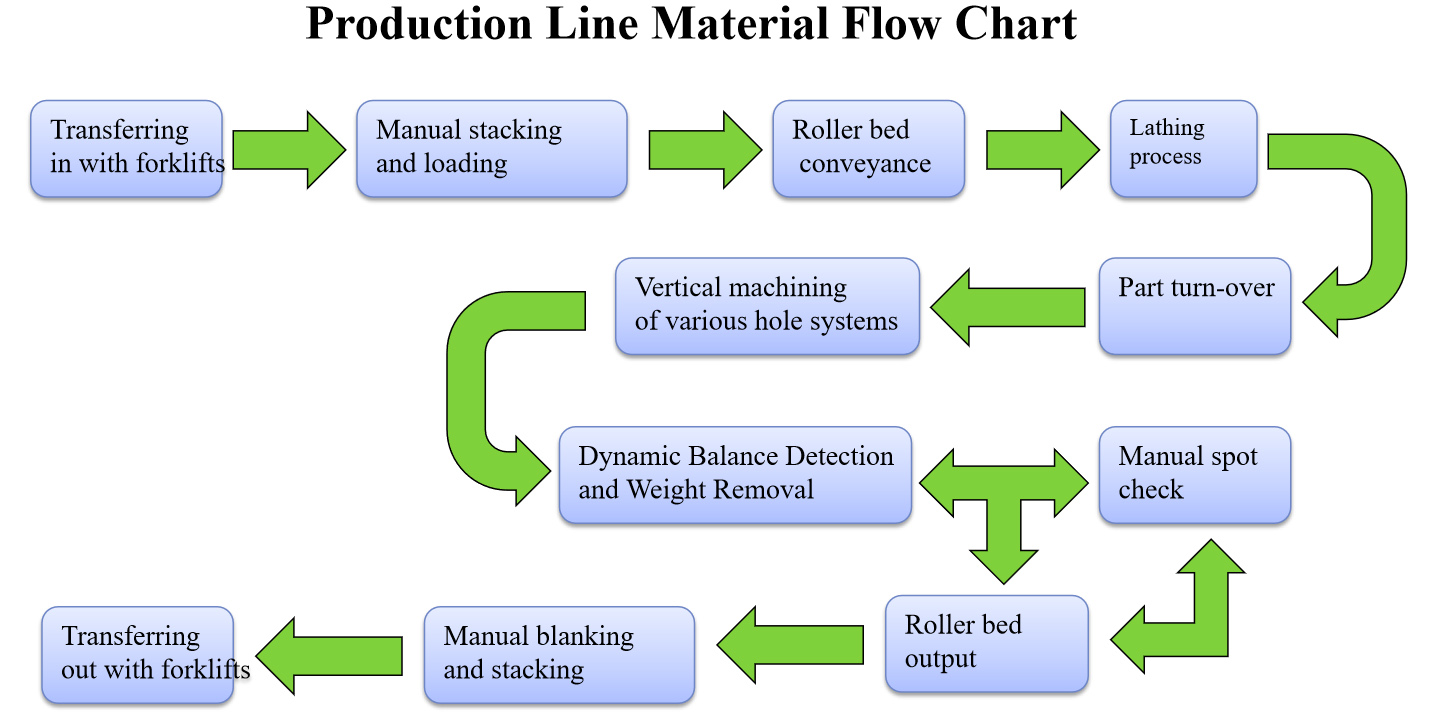

1. Likheo tsa mosebetsi li isoa liteisheneng tsa thepa ka li-forklift, li phahamisoa ka letsoho ho bethe ea rolara, 'me li romelloa liteisheneng tsa ho roala ka li-roller. Ho kenya le ho laolla mochine oa ho leka-lekanya ts'ebetsong ea lathe, ts'ebetso ea roll-over le ts'ebetso ea ho phunya le ho sila ho phethoa ke liroboto. Lihlahisoa tse feliloeng li romelloa liteisheneng tse se nang letho ka bethe ea rolara, 'me li romelloa ke li-forklifts ka mor'a hore li phahamise ka letsoho le ho bokella;

2. Lits'oants'o tse kholo tsa lisebelisoa tsa elektroniki li tla beoa lithapong tsa phetiso ea lisebelisoa ho nchafatsa le ho bonts'a tlhahisoleseling ea tlhahiso, lihlahisoa tse nang le bothata le matsatsi a tlhahiso ea polokeho ka nako ea nnete;

3. Mohala oa phetiso o tla fuoa leseli la temoso yuniti e 'ngoe le e 'ngoe, e ka bonts'ang tlhahisoleseling joalo ka e tloaelehileng, ho haella ha thepa le ho tšosa;

4. Mohala o ikemetseng o amohela mokhoa oa ho sebetsa oa yuniti le mokhoa oa ho kopanya li-unit tse ngata, o nang le sebopeho se feto-fetohang, se loketseng litlhoko tse fapaneng tsa moralo oa bareki;

5. Amohela roboto e kopanetsoeng bakeng sa ho kenya le ho koala, e nang le botsitso bo phahameng, tlhokomelo e bonolo le bophelo bo bolelele ba tšebeletso;

6. Tlhokahalo e nyane ea basebetsi. Litlhoko tsa letsatsi le letsatsi tsa basebetsi bakeng sa phetoho e 'ngoe le e 'ngoe ea mohala ona oa othomathike ke tse latelang:

Forkliftman 1 ~ 2 batho (ba okametseng ho phahamisa, ho phahamisa le ho fetisa likheo tsa mosebetsi / lihlahisoa tse felileng)

Moenjiniere oa Maintenance Motho a le mong (ea ikarabellang bakeng sa tlhokomelo ea kamehla-lichelete tsa oli le metsi, joalo-joalo)

7. Mohala o itekanetseng o na le katoloso e matla. Joalo ka machining a terata e tsoakiloeng, traceability ea mosebetsi le mesebetsi e meng, ka litšenyehelo tse tlase tsa katoloso;

Karolo ea ho kenya

1. Mohala oa bethe ea ho roala o ka boloka likotoana tse 12 × 16 = 192; 2. Bula stack ka letsoho 'me u e phahamisetse betheng ea rolara ea loading' me u e romele seteisheneng sa ho roala ka mochine oa li-roller; 3. Ka mor'a ho bula sekoti, sekoti se se nang letho se tla kenngoa 'me se behoe moleng o se nang letho oa li-trays tse se nang letho, li kenngoa ka har'a lihlopha tsa 8,' me sekoti se se nang letho se tla tlosoa ka letsoho ebe se behoa sebakeng sa polokelo;1. Mohala oa bethe ea ho roala o ka boloka likotoana tsa 12 × 16 = 192;

2. Bula stack ka letsoho 'me u e phahamisetse betheng ea rolara ea loading' me u e romele seteisheneng sa ho roala ka mochine oa li-roller;

3. Ka mor'a ho bula stack, tray e se nang letho e tla kenngoa 'me e behoe moleng o se nang letho oa li-trays tse se nang letho, li kenngoa ka har'a lihlopha tsa 8,' me sekoti se se nang letho se tla tlosoa ka letsoho ebe se behoa sebakeng sa polokelo;

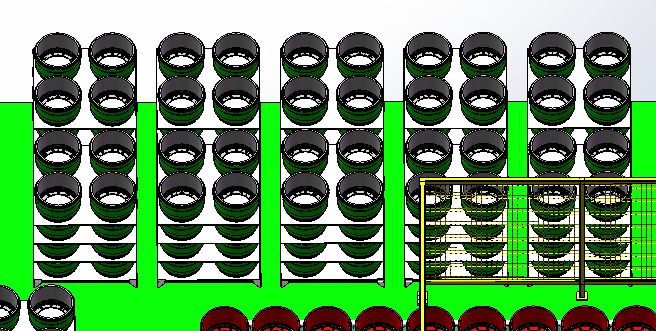

Kenyelletso ea ho sebetsa mekotla e se nang letho

1. Letlapa le le leng la likotoana tse 16 le lihlopha tse 4 ka kakaretso, tse nang le lipoleiti tsa ho arola pakeng tsa lera ka 'ngoe;

2. Mosebetsi o se nang letho o ka boloka likotoana tse 160;

3. Pallet e khothalletsoa hore e lokisoe ke moreki. Tlhokahalo: (1) Ho tiea hantle le ho batalla (2) ho khona ho hatelloa ke roboto.

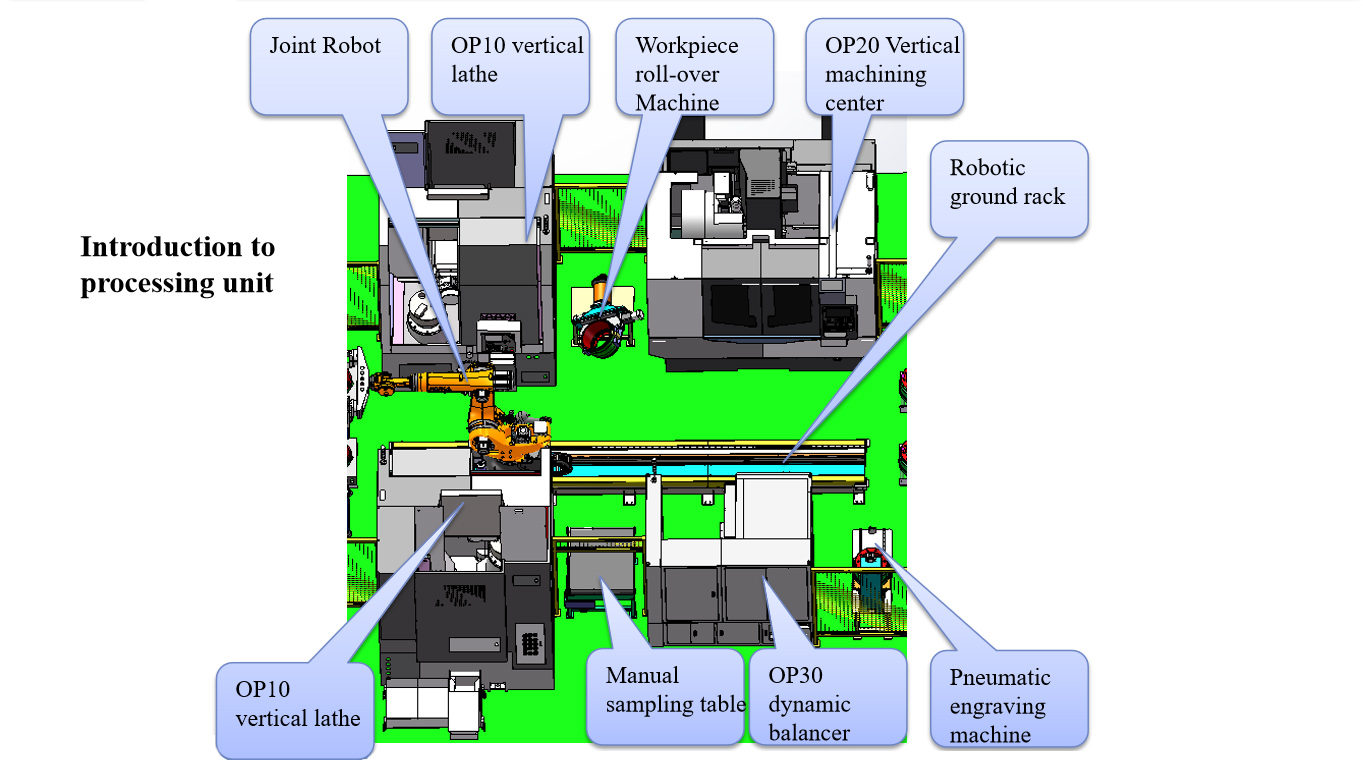

Kenyelletso ea yuniti ea ts'ebetso

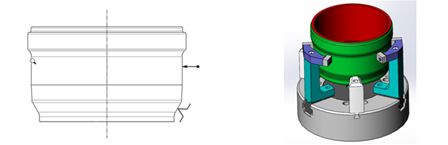

1. Ts'ebetso ea lathing e na le li-lathe tse peli tse otlolohileng, roboto ea No. 1 le robot ea fatše, e etsang machining ea selikalikoe se ka ntle, sebaka se ka hare sa sekoti le sefahleho sa ho qetela sa karolo;

2. Seteishene sa roll-over se na le mochini o le mong oa roll over, o etsang rolling over parts;

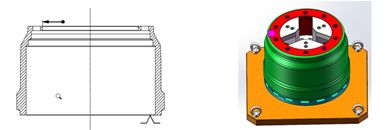

3. Ts'ebetso ea ho cheka le ho sila e na le setsi sa 1 sa vertical machining le robot e le 'ngoe ea No. 2, e etsang machining ea lesoba la ho kenya le sebaka sa ho tšoaea karolo ena.

4. Ts'ebetso e matla ea ho leka-lekanya le ho tlosa boima e na le vertical dynamic balancer, e etsang tlhahlobo e matla ea ho leka-lekanya le ho tlosa boima ba likarolo;

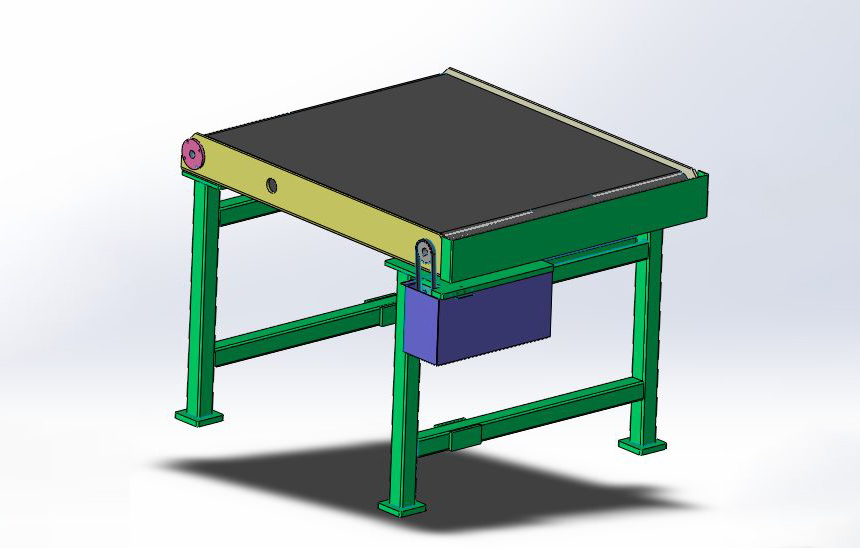

5. The manual spot check station e na le conveyor lebanta, e tsamaisang lipalangoang tsa libaka tse hlahlobiloeng le ho sebelisoa e le sethala sa tlhahlobo;

6. Setsi sa ho sebetsa sa mochine oa ho betla oa pneumatic se etsa mosebetsi oa ho betla le ho tšoaea lihlahisoa tsohle;

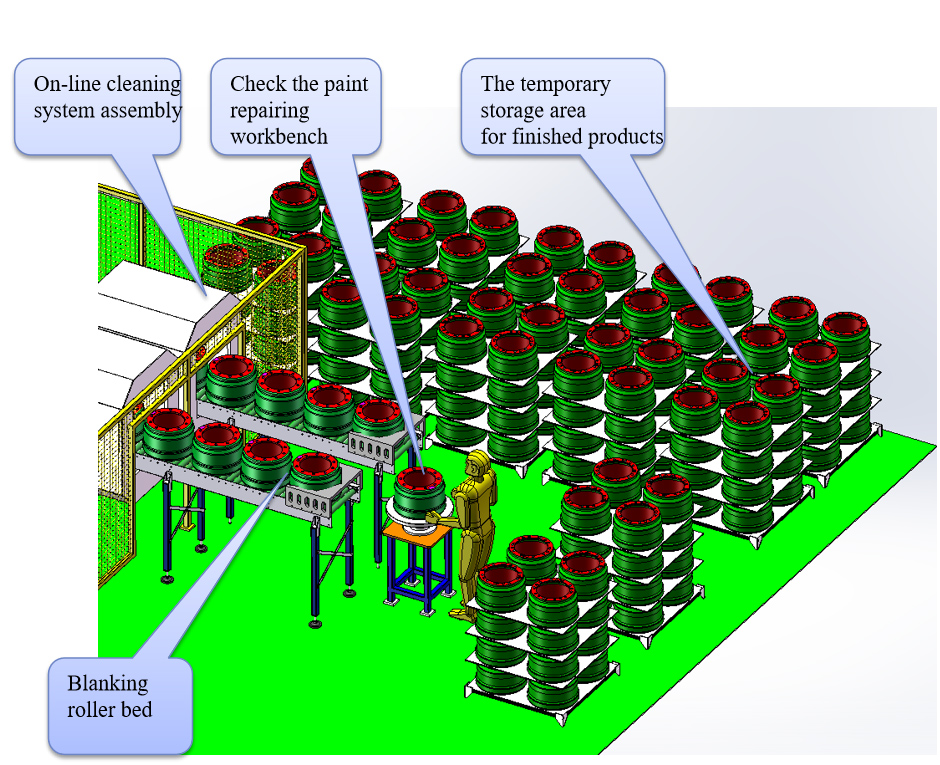

Kenyelletso ea karolo e se nang letho

1. Mohala oa bethe ea ho roala o ka boloka likotoana tse 12 × 16 = 192;

2. Li-trays le li-partition plates seteisheneng sa ho roala li isoa sebakeng se se nang letho ka li-forklifts;

3. Lihlahisoa tse feliloeng li isoa seteisheneng se se nang letho ka mochine o tsamaisang rolara, 'me li phahamisoa le ho kenngoa ka letsoho ebe li fetisetsoa ka forklifts;

Kenyelletso ea ho qeta sehlahiswa stacking

1. Letlapa le le leng la likotoana tse 16 le lihlopha tse 4 ka kakaretso, tse nang le lipoleiti tsa ho arola pakeng tsa lera ka 'ngoe;

Likotoana tse 2.192 li ka bolokoa ka har'a pokello ea lihlahisoa tse felileng;

3. Pallet e khothalletsoa hore e lokisoe ke moreki. Tlhokahalo: (1) Ho tiea hantle le ho batalla (2) ho khona ho hatelloa ke roboto.

Kenyelletso ea likarolo tse ka sehloohong tse sebetsang tsa mohala oa tlhahiso

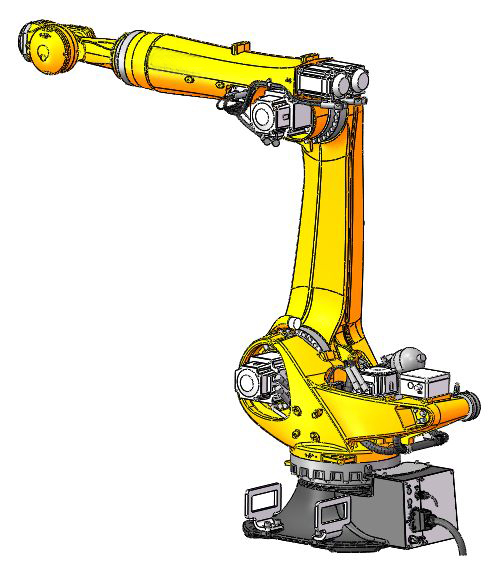

Selelekela ho Machining le Dynamic Balancing Weight Removal Unit Robot

Roboto ea Chenxuan: SDCX-RB08A3-1700

| Lintlha tsa motheo | |

| Mofuta | SDCX-RB08A3-1700 |

| Palo ea lilepe | 6 |

| Boholo ba tšireletso | 3100 limilimithara |

| Ema ho pheta-pheta (ISO 9283) | ± 0.05 limilimithara |

| Boima ba 'mele | 1134kg |

| Tlhophiso ea ts'ireletso ea roboto | Tekanyetso ea ts'ireletso, IP65 / IP67letsoho la letsoho(IEC 60529) |

| Boemo ba ho phahamisa | Siling, angle e lumelletsoeng ea tšekamelo ≤ 0º |

| Qetello ea bokaholimo, pente | Foreimi ea motheo: e ntšo (RAL 9005) |

| Mocheso oa tikoloho | |

| Tshebetso | 283 K ho isa ho 328 K (0 °C ho ea +55 °C) |

| Polokelo le lipalangoang | 233 K ho isa 333 K (-40 °C ho +60 °C) |

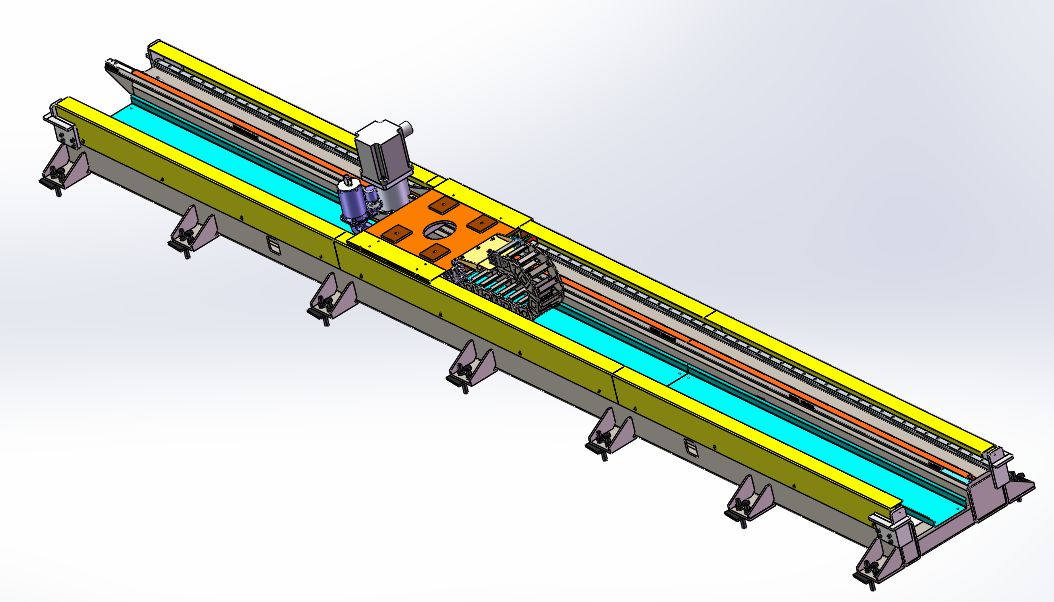

Kenyelletso ea Robot Travel Axis

Sebopeho sena se entsoe ka roboto e kopanetsoeng, koloi ea servo le pinion le rack drive, e le hore roboto e ka etsa motsamao oa rectilinear pele le morao. E hlokomela mosebetsi oa roboto e le 'ngoe e sebeletsang lisebelisoa tse ngata tsa mochini le lisebelisoa tsa ho ts'oara liteisheneng tse' maloa mme e ka eketsa ts'ebetso ea liroboto tse kopaneng;

Pina ea ho tsamaea e sebelisa setsi se cheselitsoeng ka liphaephe tsa tšepe 'me se tsamaisoa ke servo motor, pinion le rack drive, ho eketsa ts'ebetso ea ts'ebetso ea roboto e kopanetsoeng le ho ntlafatsa ka katleho sekhahla sa tšebeliso ea roboto;

Tsela ea ho tsamaea e kenngoa fatše;

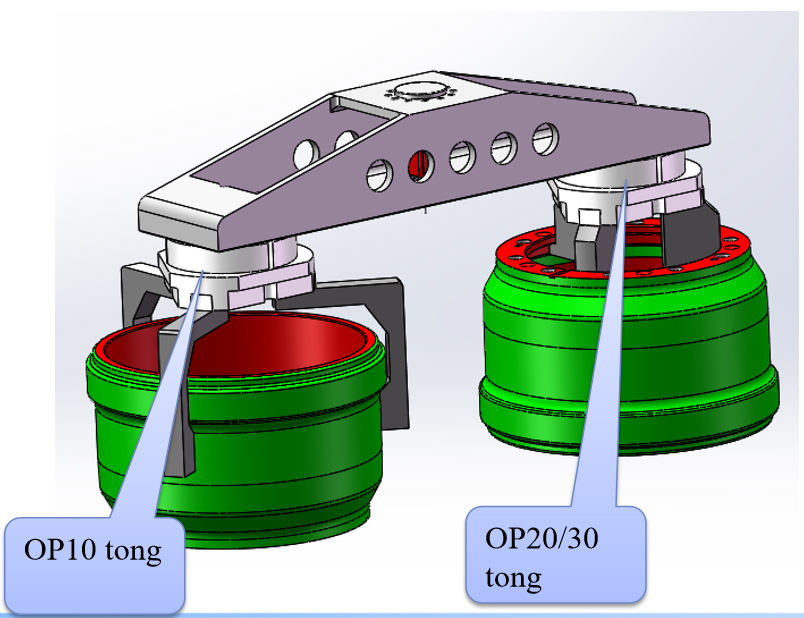

Kenyelletso ea tongs ea liroboto tse kenyang le tse koalang letho

Tlhaloso:

1. Ho latela litšoaneleho tsa karolo ena, re nka bokaholimo ba maqhubu a kantle a melapo e meraro;

2. Mochine o na le mochine oa ho lemoha boemo le mochine oa khatello ea khatello ho bona hore na boemo ba clamping le khatello ea likarolo li tloaelehile;

3. Mochine o na le mochine oa khatiso, 'me mochine oa mosebetsi o ke ke oa oa ka nako e khutšoanyane haeba ho senyeha ha matla le ho khaoha ha khase ea potoloho e kholo ea moea;

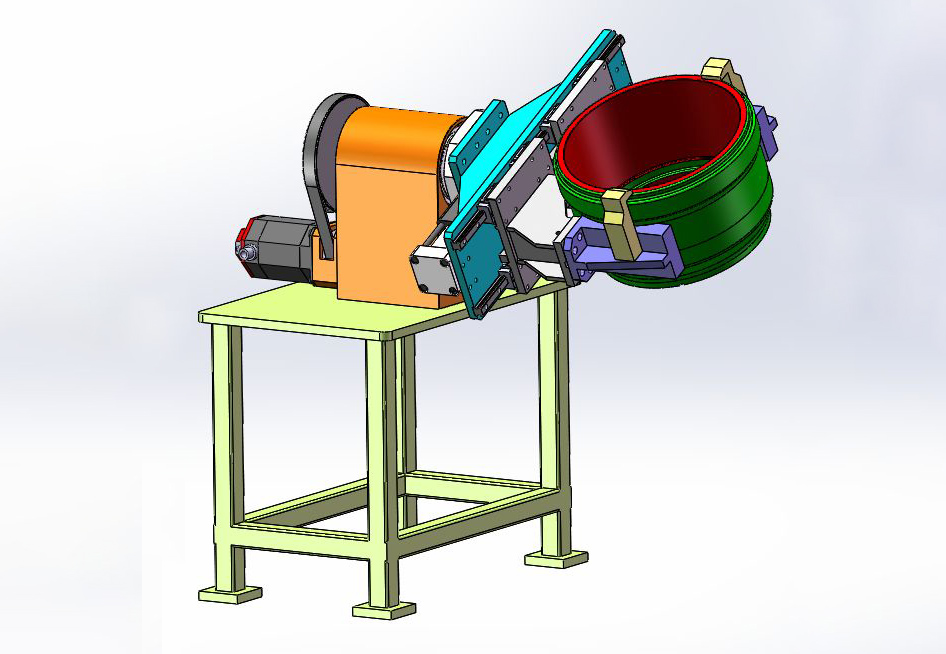

Kenyelletso ea Mochini o Iketselitsoeng oa ho Roll-over

Tlhaloso:

Mochine ona o entsoe ka foreimi e tsitsitseng, kopano ea motheo ea tšehetso le kopano ea tong ea pneumatic. E na le ts'ebetso e thibelang ho hlephileng le e thibelang ho theoha ka mor'a hore moea o khaotse, 'me e khona ho lemoha 180 ° roll over ea line workpieces;

Kenyelletso ea benche ea ho hlahloba sebaka sa matsoho

Tlhaloso:

1. Beha mefuta e fapaneng ea lisampole tse sa reroang tsa tataiso bakeng sa mekhahlelo e fapaneng ea tlhahiso, e ka laolang katleho ea litekanyo tsa inthanete;

2. Litaelo tsa Tšebeliso: The manipulator e tla beha workpiece sebakeng se behiloeng holim'a benche ea ho hlahloba letheba ho latela maqhubu a behiloeng ka letsoho, 'me a potlakele ka lebone le khubelu. Mohlahlobi o tla tobetsa konopo ho tsamaisa mosebetsi oa ho sebetsa sebakeng sa tšireletso ka ntle ho tšireletso, a ntše mosebetsi oa ho lekanya ebe o o khutlisetsa betheng ea rolara ka mor'a tekanyo;

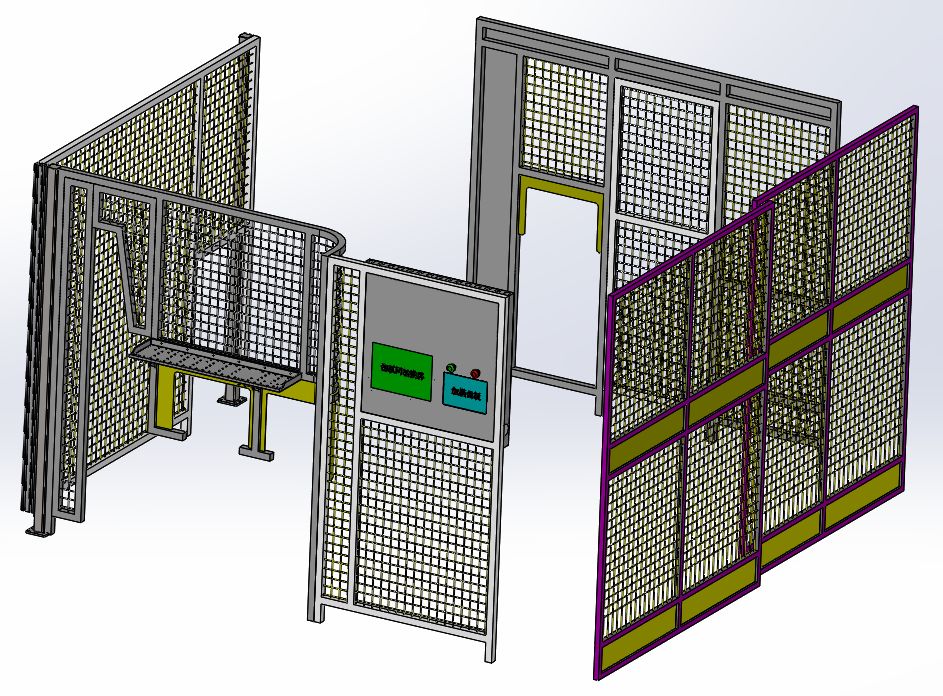

Likarolo tse sireletsang

E entsoe ka profil ea aluminium e bobebe (40 × 40) + mesh (50 × 50), 'me skrine ea ho ama le konopo ea ho emisa ts'ohanyetso e ka kopanngoa le likarolo tse sireletsang, tse kopanyang polokeho le botle bo botle.

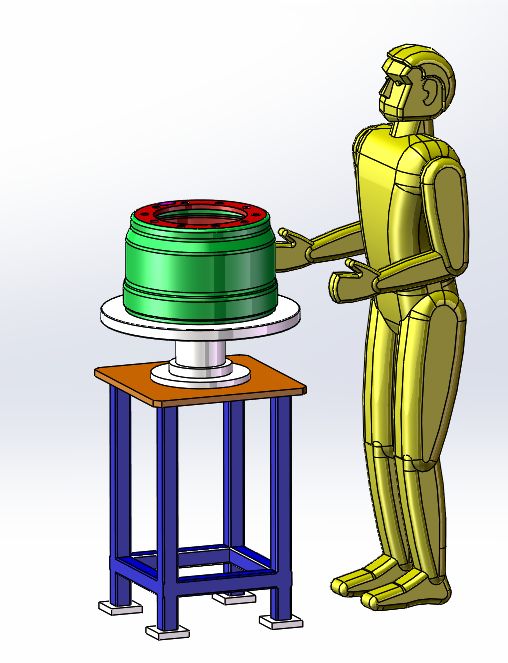

Selelekela Setsing sa Tlhahlobo bakeng sa ho lokisa pente

Tlhaloso:

Mochine ona o entsoe ka foreimi e tsitsitseng le turntable. Basebeletsi ba phahamisa lihlahisoa tse phethiloeng ho turntable, ho potoloha turntable, ho hlahloba hore na ho na le li-bumps, li-scratches le liketsahalo tse ling, 'me ka nako e loketseng ho lokisa mefokolo ea ho phunya le bokaholimo ba pente;