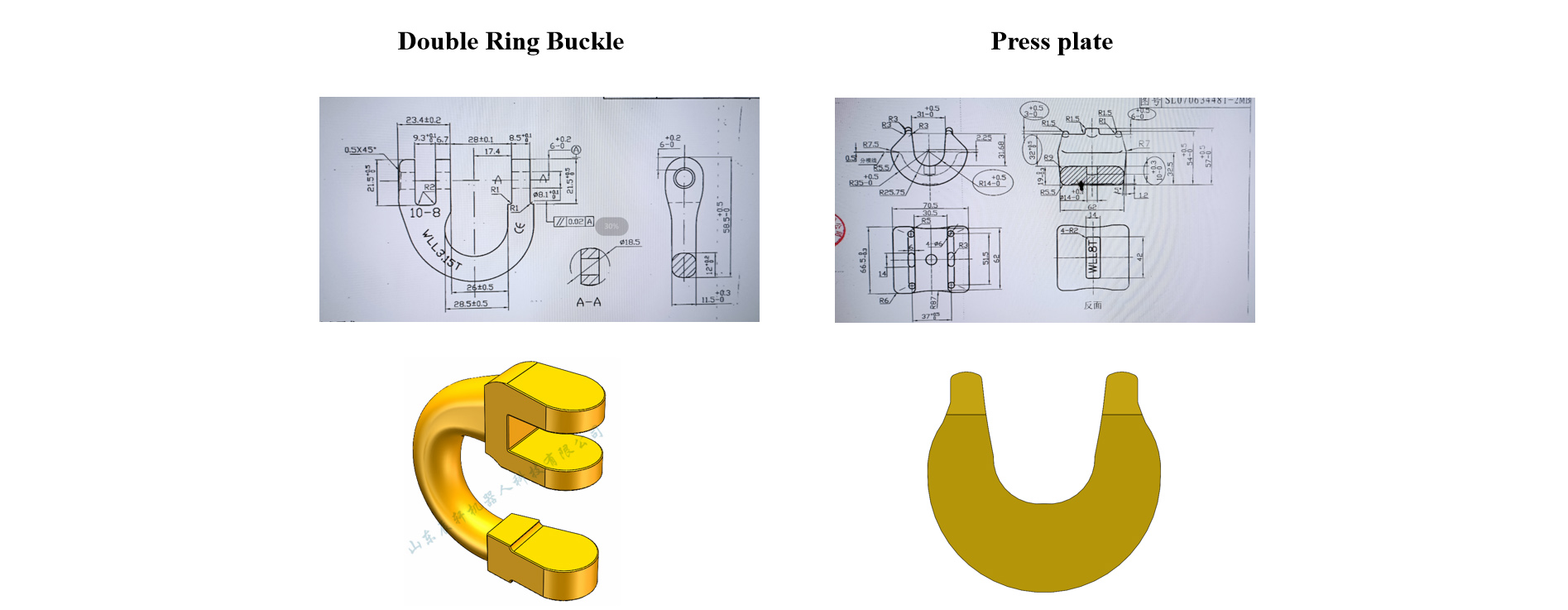

Tlhaloso ea morero

Lits'oants'o tsa Mosebetsi: Ho ipapisitsoe le litšoantšo tsa CAD tse fanoeng ke Party A Litlhoko tsa tekheniki: Ho kenya boholo ba polokelo ea silo ≥bokhoni ba tlhahiso ka hora e le 'ngoe.

| Mofuta oa mosebetsi | Tlhaloso | Nako ea ho sebetsa | Chelete ea polokelo / hora | Palo ea lithapo | Tlhokahalo |

| Letlapa la khatiso la SL-344 | 1T/2T/3T | 15 | 240 | 1 | E tsamaellana |

| 5T/8T | 20 | 180 | 1 | E tsamaellana | |

| SL-74 Habeli Ring Buckle | 7/8-8 | 24 | 150 | 2 | / |

| 10-8 | 25 | 144 | 2 | / | |

| 13-8 | 40 | 90 | 2 | / | |

| 16-8 | 66 | 55 | 1 | / | |

| 20-8 | 86 | 42 | 2 | / |

Setšoantšo sa mosebetsi, mohlala oa 3D

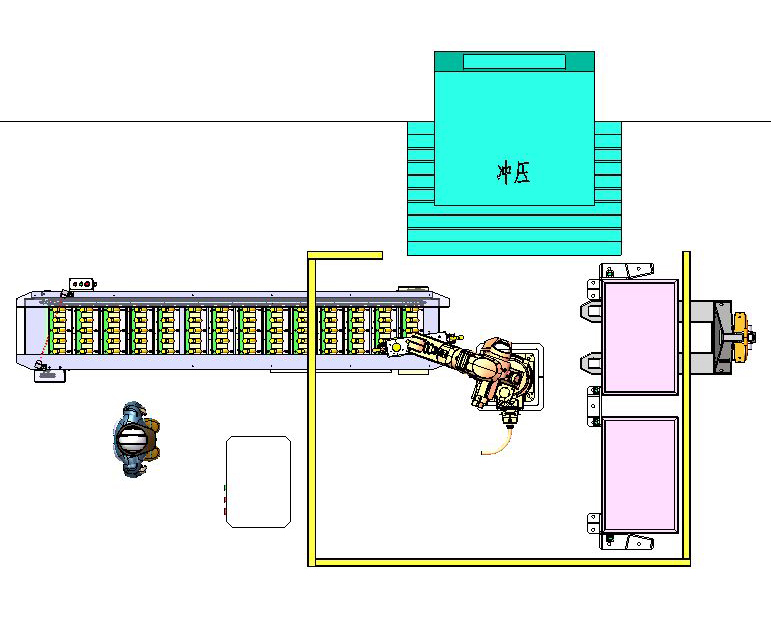

Moralo oa Leano

Tlhaloso: Lintlha tse qaqileng tsa ho lula ha mobu li tla itšetleha ka moralo.

Lethathamo la Lisebelisoa

Baskete bakeng sa polokelo ea nakoana ea lipoleiti tsa karohano

| S/N | Lebitso | Mohlala No. | Bongata. | Litlhaloso |

| 1 | Liroboto | XB25 | 1 | Chenxuan (ho kenyeletsoa 'mele, khabinete ea taolo le pontšo) |

| 2 | Letlapa la roboto | Boikemisetso | 1 | Chenxuan |

| 3 | Motheo oa liroboto | Boikemisetso | 1 | Chenxuan |

| 4 | Sistimi ea Taolo ea Motlakase | Boikemisetso | 1 | Chenxuan |

| 5 | E kenya conveyor | Boikemisetso | 1 | Chenxuan |

| 6 | Lekhoakhoa la tšireletso | Boikemisetso | 1 | Chenxuan |

| 7 | Sesebediswa sa ho bona se behang foreimi | Boikemisetso | 2 | Chenxuan |

| 8 | Sekheo se se nang letho | / | 2 | E lokiselitsoe ke Party A |

Tlhaloso: Lethathamo le bonts'a lethathamo la litlhophiso tsa sebaka sa mosebetsi sa motho ka mong.

Tlhaloso ea tekheniki

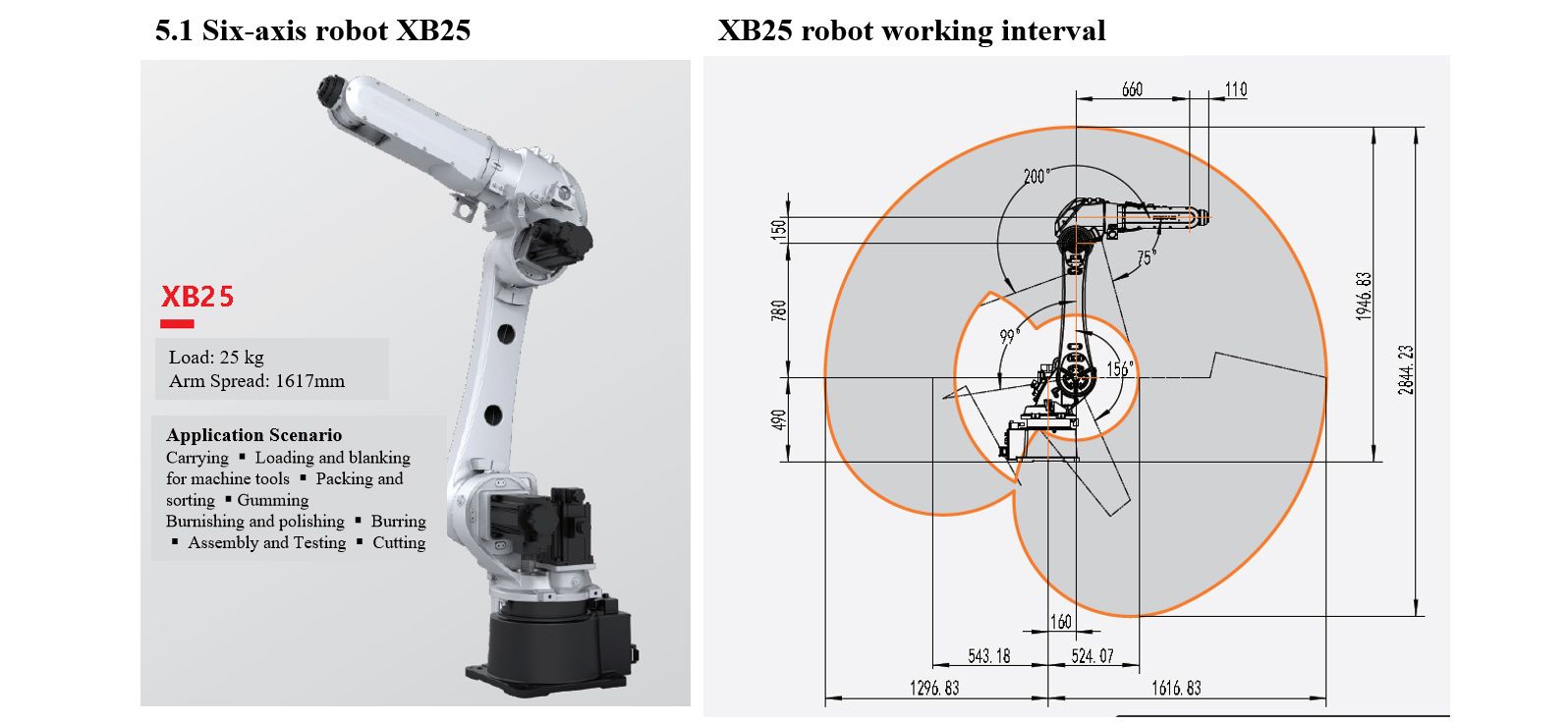

Roboto ea li-axis tse tšeletseng XB25

Roboter XB25 als grundlegende parameter

| Mohlala No. | Degree ea Tokoloho | Mojaro oa Letsoho | Boholo ba radius ea ho sebetsa | ||||||||

| XB25 | 6 | 25kg | 1617 limilimithara | ||||||||

| Ho nepahala ha maemo a phetoang | Boima ba mmele | Mophato wa tshireletso | Mokhoa oa ho kenya | ||||||||

| ± 0.05mm | Hoo e ka bang. 252kg | IP65(Wrist IP67) | Fatše, e emisitsoe | ||||||||

| Mohloli o kopaneng oa moea | Mohloli o Kopantsoeng oa Letšoao | Matla a lekantsoeng a transformer | Selaoli se ts'oanang | ||||||||

| 2-φ8 peipi ea moea (8 bar, solenoid valve bakeng sa khetho) | Letšoao la likanale tse 24 (30V, 0.5A) | 9.5kVA | XBC3E | ||||||||

| Lekhalo la ho sisinyeha | Lebelo le phahameng | ||||||||||

| Shaft 1 | Shaft 2 | Shaft 3 | Shaft 4 | Shaft 5 | Shaft 6 | Shaft 1 | Shaft 2 | Shaft 3 | Shaft 4 | Shaft 5 | Shaft 6 |

| +180°/-180° | +156°/-99° | +75°/-200° | +180°/-180° | +135°/-135° | +360°/-360° | 204°/S | 186°/S | 183°/S | 492°/S | 450°/S | 705°/S |

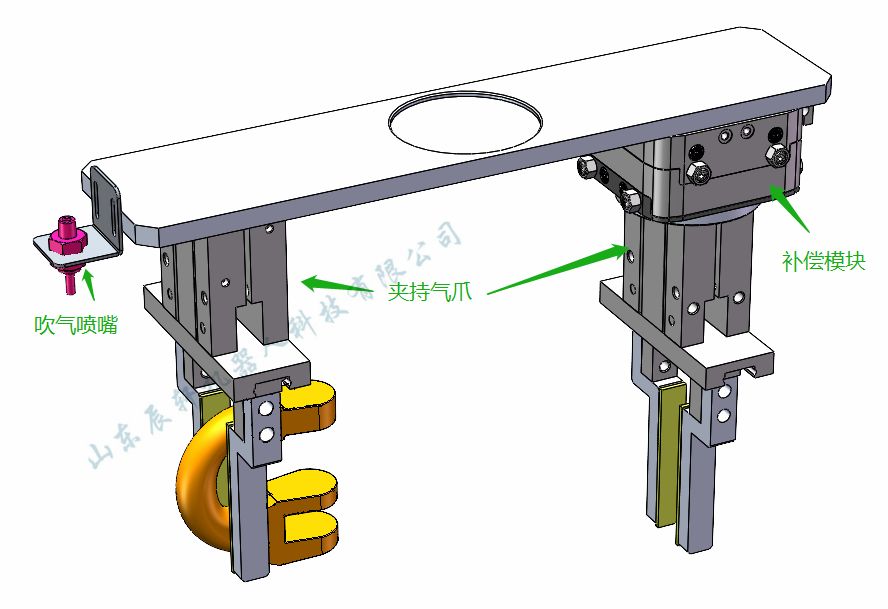

Letlapa la roboto

1. Moralo oa liteishene tse peli, phallo e kopaneng le ho koala, e khona ho hlokomela ts'ebetso ea ho kenya hape ka potlako;

2. E sebetsa feela ho li-clamp workpieces tsa litlhaloso tse boletsoeng, 'me tong e lumellana feela le ho tiisa li-workpieces tse tšoanang ka har'a mefuta e itseng;

3. Ho ts'oara motlakase ho tiisa hore sehlahisoa se ke ke sa oa ka nako e khutšoanyane, se bolokehileng le se ka tšeptjoang;

4. Sehlopha sa li-nozzles tsa pneumatic tse lebelo le phahameng li ka kopana le mosebetsi oa ho letsa moea setsing sa mechine;

5. Lisebelisoa tse bonolo tsa polyurethane li tla sebelisoa bakeng sa ho koala menoana ho qoba ho pinching ea workpiece;

6. Mojule oa matšeliso o ka buseletsa ka mokhoa o ikemetseng boemo ba mosebetsi kapa liphoso tsa sebopeho le phapang ea mamello ea workpiece.

7. Setšoantšo ke sa ho bua feela, 'me lintlha li tla itšetleha ka moralo oa sebele.

| Lintlha tsa Tekheniki* | |

| Odara No. | XYR1063 |

| Ho hokahanya li-flange ho latela EN ISO 9409-1 | TK 63 |

| Mojaro o khothalelitsoeng [kg]** | 7 |

| X/Y maeto a axis +/- (mm) | 3 |

| Center Retention Force (N] | 300 |

| Non-center Retention Force [N] | 100 |

| Khatello e phahameng ea moea e sebetsang [bar] | 8 |

| Mocheso o tlase oa ho sebetsa [°C] | 5 |

| Mocheso o phahameng oa ho sebetsa [°C] | +80 |

| Bophahamo ba moea bo sebelisoang ka potoloho [cm3] | 6.5 |

| Motsotso oa inertia [kg/cm2] | 38.8 |

| Boima [kg] | 2 |

| * Lintlha tsohle li lekantsoe ka khatello ea moea ea 6 bar **Ha li bokane setsing |

Mojule oa matšeliso

Mojule oa matšeliso o ka lefella ka bohona boemo ba workpiece kapa liphoso tsa sebopeho le phapang ea mamello ea mosebetsi.

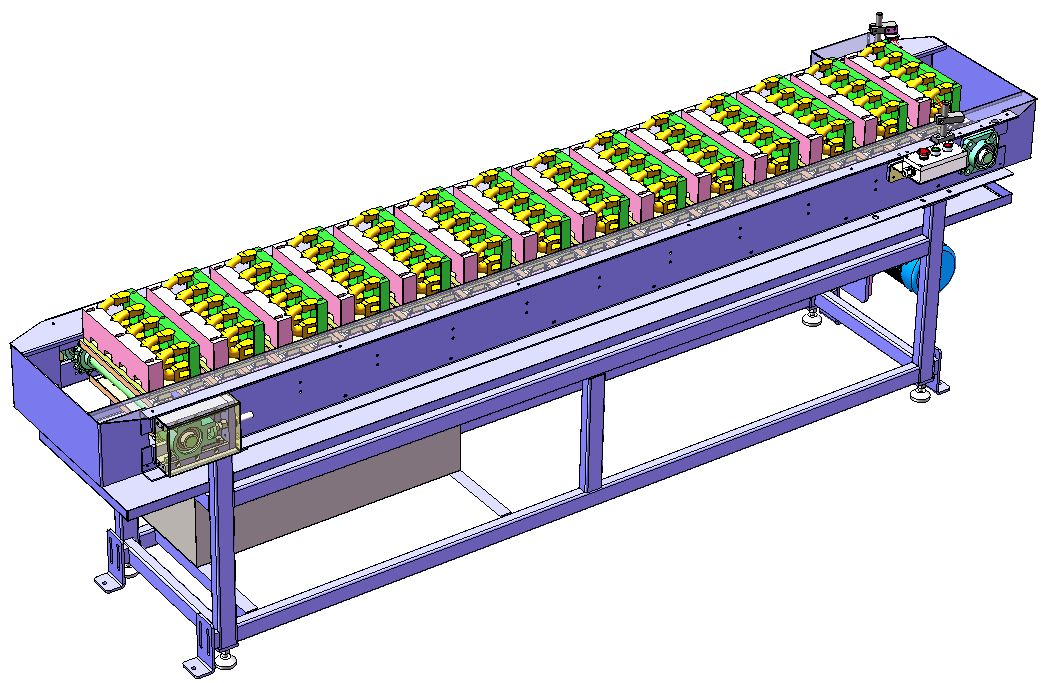

Mohala oa ho kenya le oa ho tsamaisa

1. Mohala oa ho roala le oa ho tsamaisa o amohela sebopeho sa ketane ea lera le le leng, se nang le bokhoni bo boholo ba polokelo, ts'ebetso e bonolo ea matsoho le ts'ebetso e phahameng ea litšenyehelo;

2. Palo e entsoeng ea lihlahisoa tse behiloeng li tla kopana le matla a tlhahiso ea hora e le 'ngoe. Tlas'a boemo ba ho fepa ka letsoho kamehla metsotso e meng le e meng e 60, ts'ebetso ntle le ho koala e ka phethahala;

3. Terei ea lintho tse bonahalang e na le liphoso, ho thusa ho ntša metsi ka letsoho, le lisebelisoa tsa silo bakeng sa lisebelisoa tsa litlhaloso tse fapaneng li tla lokisoa ka letsoho;

4. Lisebelisoa tsa oli le metsi, tse thibelang likhohlano le tse matla haholo li khethoa bakeng sa terei ea ho fepa ea silo, 'me ho hlokahala hore ho lokisoe ka letsoho ha ho hlahisoa lihlahisoa tse fapaneng;

5. Setšoantšo ke sa ho bua feela, 'me lintlha li tla itšetleha ka moralo oa sebele.

Sistimi ea Taolo ea Motlakase

1. Ho kenyelletsa taolo ea tsamaiso le puisano ea lipontšo pakeng tsa lisebelisoa, ho kenyelletsa le li-sensor, lithapo, li-trunking, li-switches, joalo-joalo;

2. Sehlopha sa othomathike se entsoe ka lebone la alamo la mebala e meraro. Nakong ea ts'ebetso e tloaelehileng, lebone la mebala e meraro le bontša botala; 'me haeba yuniti e hlōleha, lebone la mebala e meraro le tla bontša alamo e khubelu ka nako;

3. Ho na le likonopo tsa ho emisa ts'ohanyetso holim'a khabinete ea taolo le lebokose la pontšo ea roboto. Boemong ba tšohanyetso, konopo ea ho emisa ts'ohanyetso e ka hatelloa ho hlokomela setopo sa ts'ohanyetso sa sistimi le ho romella lets'oao la alamo ka nako e ts'oanang;

4. Ka pontšo, re ka bokella mefuta e mengata ea mananeo a kopo, a ka finyellang litlhoko tsa ho nchafatsa lihlahisoa le ho eketsa lihlahisoa tse ncha;

5. Lipontšo tsohle tsa ho emisa ts'ohanyetso tsa tsamaiso eohle ea taolo le matšoao a ts'ireletso ea tšireletso pakeng tsa lisebelisoa tsa ts'ebetso ea bosholu le liroboto li hokahane le tsamaiso ea tšireletso 'me taolo e koetsoeng e etsoa ka lenaneo la taolo;

6. Tsamaiso ea tsamaiso e hlokomela khokahanyo ea pontšo har'a lisebelisoa tsa ts'ebetso tse kang liroboto, li-silos, li-tong le lisebelisoa tsa mochine oa mochine;

7. Sistimi ea lisebelisoa tsa mochini e hloka ho hlokomela phapanyetsano ea matšoao le sistimi ea liroboto.

Sesebelisoa sa Mochini oa ho sebetsa (e fanoe ke mosebelisi)

1. Sesebelisoa sa mochine oa mochine se tla ba le mochine o ikemetseng oa ho tlosa li-chip (kapa ho hloekisa lisebelisoa tsa tšepe ka letsoho le kamehla) le ts'ebetso ea ho bula le ho koala lemati (haeba ho na le ts'ebetso ea ho bula le ho koala lemati);

2. Nakong ea ts'ebetso ea mochine, li-chips tsa tšepe ha lia lumelloa ho pota-pota li-workpieces, tse ka amang ho koala le ho behoa ha li-workpieces ka liroboto;

3. Ha ho nahanoa ka monyetla oa hore litšila tsa chip li oele ka har'a hlobo ea mochine oa mochine, Mokha oa B o eketsa mosebetsi oa ho letsa moea ho li-tongs tsa roboto.

4. Mokha oa A o tla khetha lisebelisoa tse nepahetseng kapa thekenoloji ea tlhahiso ho netefatsa bophelo bo loketseng ba lisebelisoa kapa ho fetola lisebelisoa ka mochine o fetolang ka har'a mochine oa mochine, e le ho qoba ho ama boleng ba mochine oa mochine ka lebaka la ho roala ha lisebelisoa.

5. Puisano ea pontšo pakeng tsa sesebelisoa sa mochine le roboto e tla kenngoa ts'ebetsong ke Mokha oa B, 'me Mokha oa A o tla fana ka matšoao a nepahetseng a sesebelisoa sa mochine kamoo ho hlokahalang.

6. Roboto e tsamaisa maemo a thata ha e khetha likarolo, 'me sesebelisoa sa mochini se hlokomela boemo bo nepahetseng ho latela sebaka sa boits'oaro sa workpiece.

Lekhoakhoa la tšireletso

1. Beha terata e sireletsang, lemati la tšireletso, senotlolo sa tšireletso le lisebelisoa tse ling, 'me u etse tšireletso e hlokahalang ea ho koala.

2. Lemati la tšireletso le tla behoa sebakeng se nepahetseng sa terata ea tšireletso. Menyako eohle e tla ba le sesebelisoa sa polokeho le konopo, konopo ea reset le konopo ea ho emisa ts'ohanyetso.

3. Monyako oa tšireletso o hokahane le tsamaiso ka senotlolo sa polokeho (switch). Ha lemati la polokeho le buloa ka mokhoa o sa tloaelehang, sistimi ea emisa ebe e fana ka alamo.

4. Mehato ea ts'ireletso ea ts'ireletso e tiisa polokeho ea basebetsi le lisebelisoa ka hardware le software.

5. Lekhoakhoa la tšireletso le ka fanoa ke Party A ka boeena. Ho kgothaletswa ho tjheseletsa ka marang-rang a boleng bo holimo le ho penta ka varnish e mosehla e lemosang ka holim'a metsi.

Lekhoakhoa la tšireletso

Senotlolo sa polokeho

Polokeho terata Sebaka sa ts'ebetso (e fanoe ke Mokha oa A)

| Phepelo ea motlakase | Phepelo ea motlakase: Mehato e meraro ea terata ea AC380V ± 10%, mefuta e fapaneng ea ho feto-fetoha ha motlakase ± 10%, khafetsa: 50HZ; Phepelo ea matla ea khabinete ea taolo ea liroboto e tla ba le sesebelisoa sa moea se ikemetseng; Khabinete ea taolo ea liroboto e tlameha ho theoa ka mokhoa oa ho hanyetsa fatše ka tlase ho 10Ω;Sebaka se sebetsang pakeng tsa mohloli oa matla le khabinete ea taolo ea motlakase ea liroboto e tla ba ka hare ho limithara tse 5. |

| Mohloli oa moea | Moea o hatelitsoeng o tla tlhotluoa ka ntle ho metsi, khase le litšila, 'me khatello e tsoang ka mor'a ho feta FRL e tla ba 0.5 ~ 0.8Mpa; Sebaka se sebetsang pakeng tsa mohloli oa moea le 'mele oa roboto e tla ba ka hare ho limithara tse 5. |

| Motheo | Tšoara ka mokato o tloaelehileng oa samente oa workshop ea Party A, 'me motheo oa ho kenya thepa ka' ngoe o tla beoa fatše ka liboutu tse atolositsoeng; Matla a konkreite: 210 kg / cm2;Botenya ba konkreite: Ho feta 150 mm;Ho se lekane ha motheo: Ka tlase ho ± 3mm. |

| Maemo a Tikoloho | Mocheso oa tikoloho: 0 ~ 45 ℃;Mongobo o amanang: 20% ~ 75%RH (ha ho condensation e lumelloa); Ho potlakisa ho sisinyeha: Ka tlase ho 0.5G. |

| Tse fapaneng | Qoba likhase tse chesang le tse senyang le maro, 'me u se ke ua fafatsa oli, metsi, lerōle, joalo-joalo; U se ke ua atamela mohloli oa lerata la motlakase. |